When Ignoring Your Fuel System Leads to Bigger Headaches

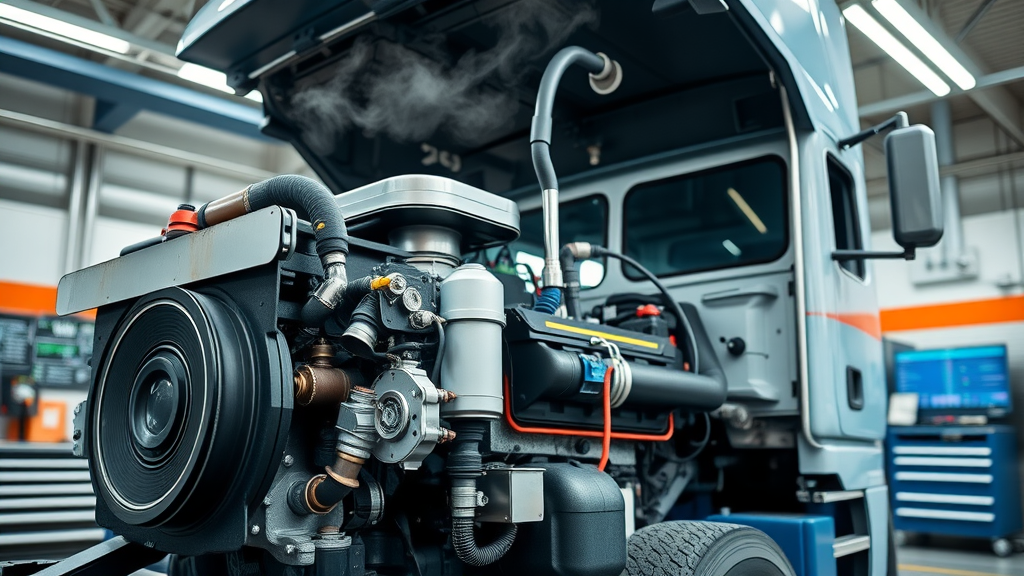

You might not see it, but your engine’s fuel system is where reliability and performance are made—or lost. Problems in these hidden pathways result in rough starts, poor fuel economy, or even complete breakdowns far from help. In many ways, fuel system services are the quiet guardians of every engine-dependent operation, from cross-country trucking to backbreaking days on the farm. Overlooking their care is like ignoring the foundation of a house—cracks may not show up today, but expensive trouble is inevitable.

Companies and individuals relying on diesel or gas-powered vehicles and equipment face a non-negotiable truth: efficient, clean fuel delivery isn’t just about power; it’s about cost, compliance, and confidence. Whether you operate a heavy-duty tractor, a long-haul truck, or industrial machinery, skipping regular fuel system services risks not just breakdowns, but missed work, regulatory headaches, and mounting frustration. Understanding what’s truly involved in fuel system care is the difference between smooth-running operations and chronic engine woes. For those frustrated by confusing symptoms—or simply wanting peace of mind—it’s essential to understand what dedicated fuel system services really provide.

Why Understanding Fuel System Services Could Save Your Engine—and Your Wallet

At its core, fuel system services encompass diagnostic checks, detailed inspections, repairs, and replacement or rebuilding of fuel delivery components. When fuel systems—whether integrated in diesel, agricultural, or industrial equipment—fall out of tune, the consequences are severe: power loss, missed deadlines, and ever-rising operational costs. Incorporating expert-level fuel system services ensures that your engine isn’t just patched up, but deeply evaluated and optimized for both today's rigorous standards and tomorrow's heavy tasks.

The complexity of modern engines means that something as small as a worn injector, a faulty pump, or even microscopic contaminants can ripple out into destructive engine failure. Engines now operate at higher pressures and tighter tolerances than ever, and their fuel systems must be precisely maintained and calibrated. Those who only react after failures pay a higher price—through costly emergency repairs, extended downtime, or even early engine replacements. Understanding the necessity and value of fuel system services arms equipment owners and operators with the confidence to take proactive control of their engine’s health, ultimately saving substantial time and money.

Why Accurate Fuel System Services Have Become a Non-Negotiable in Engine Management

In the rapidly evolving world of engine technology, expert businesses in the Stockton region have become known for thorough, unbiased appraisals and solutions for everything from vintage big cam III PT systems to contemporary ISX high pressure common rail technology. Acting as both a resource and a partner, their approach is guided by the principle that “information may come at a price, but it is not as expensive as ignorance.” Their experienced staff offer options: from testing and reconditioning to complete replacement, empowering customers with real, actionable data on their equipment’s fuel systems.

The true benefit of comprehensive fuel system services is not just in fixing problems, but in preventing them. Accurate diagnostics and targeted issues correction mean that operators enjoy longer engine lifespans, fewer unexpected issues, and greater compliance with ever-tightening emissions and performance standards. With a diverse inventory that covers all major Cummins engine models and a non-proprietary approach to diagnostic tools, customers benefit from immediate access to crucial parts and support—without unnecessary delays or hidden dependencies. In a business where downtime equals dollars lost, this expert, transparent approach to fuel system services is transformative for productivity and peace of mind.

The Evolution of Fuel System Care: From Trial-and-Error to Precision Diagnostics

Engine and equipment maintenance has dramatically transformed over the past decades. Where mechanics once relied on intuition and trial-and-error, today’s fuel system services utilize factory-certified diagnostics and precise component testing. Every part, from injectors to fuel pumps, can be analyzed for wear, contamination, or failure—often before symptoms show. For every owner of agricultural workhorses or modern diesel trucks, this can mean the difference between routine maintenance and catastrophic engine failure.

This shift means that educated decisions can now be made: Is rebuilding a cost-effective option, or is full replacement the smarter investment? Accessible testing and evaluation—supported by non-restrictive diagnostic tools—lets both in-house technicians and independent repair professionals get fast, accurate answers. The move from guesswork to precision not only boosts confidence but also allows equipment managers to schedule repairs with minimal disruption, plan budgets with confidence, and reduce both environmental and financial waste.

How Preventive Fuel System Services Extend the Life of Your Equipment

Preventive maintenance, especially for fuel systems, has become a cornerstone of efficient engine management. Catching small concerns before they become major failures means more time working and less time waiting for repairs. By prioritizing regular inspections, cleaning, and targeted component replacement, operators see a measurable reduction in unexpected breakdowns—and, as a direct result, lower overall operating costs.

In a market where emissions regulations are increasingly strict and the drive for efficiency is relentless, an expertly calibrated fuel system isn’t just a technical detail—it’s a competitive advantage. Responding to these demands, industry professionals support both warranty-backed repairs and independent diagnostics, removing needless bottlenecks and giving customers the choice to handle issues how and when it best suits their work. Such flexibility has changed the landscape for farms, fleets, and industrial firms alike.

What You Gain By Choosing Knowledgeable Fuel System Service Providers

Working with specialists who invest in ongoing training, precision equipment, and customer empowerment guarantees that every fuel system service is performed to the highest standard. Teams with average tenures exceeding a decade bring unmatched experience to even the toughest diagnostic challenges. Their mix of deep product knowledge, access to full inventories, and direct, honest communication positions clients to make the best possible decisions.

This approach isn’t about simply fixing what’s broken. It’s about helping customers maintain long-term engine health and efficiency through each repair or inspection, offering transparent advice and straightforward quotes. Empowerment extends beyond the shop floor: customers can access the same diagnostic tools, reducing unnecessary delays and ensuring their needs remain front and center. The end goal is clear—greater reliability, safer operations, and the peace of mind that comes from knowing the job was done right the first time.

In Their Own Words: Fuel System Service Trust Earned Through Results

Firsthand experiences often say the most about the value of skilled fuel system services. Real-life feedback not only reflects a company's expertise but also validates the importance of partnering with experienced professionals for these critical repairs.

They guys and girls know their stuff had parts in stock

—Ronnie M.

This kind of direct validation highlights what every equipment owner wants—immediate, knowledgeable service and access to necessary parts without delay. When others discover such reliable results, it becomes clear that skilled fuel system services truly are a safeguard against unexpected breakdowns and a way to guarantee productivity stays on track.

Fuel System Services: Powering Confidence, Precision, and Engine Longevity

The investment in professional fuel system services pays off in more ways than basic repairs alone. At a time when engines are more powerful, efficient, and regulated than ever, having an expert partner makes all the difference. The knowledgeable approach, commitment to fast solutions, and customer-first mindset demonstrated by industry leaders continue to shape the region’s reputation for engine excellence.

By choosing precise, full-scope fuel system services, equipment owners position themselves for fewer costly surprises, smoother operations, and lasting engine strength. These services are no longer just an option—they’re a safeguard for the future of every valuable engine, ensuring compliance, efficiency, and the confidence to face any job ahead.

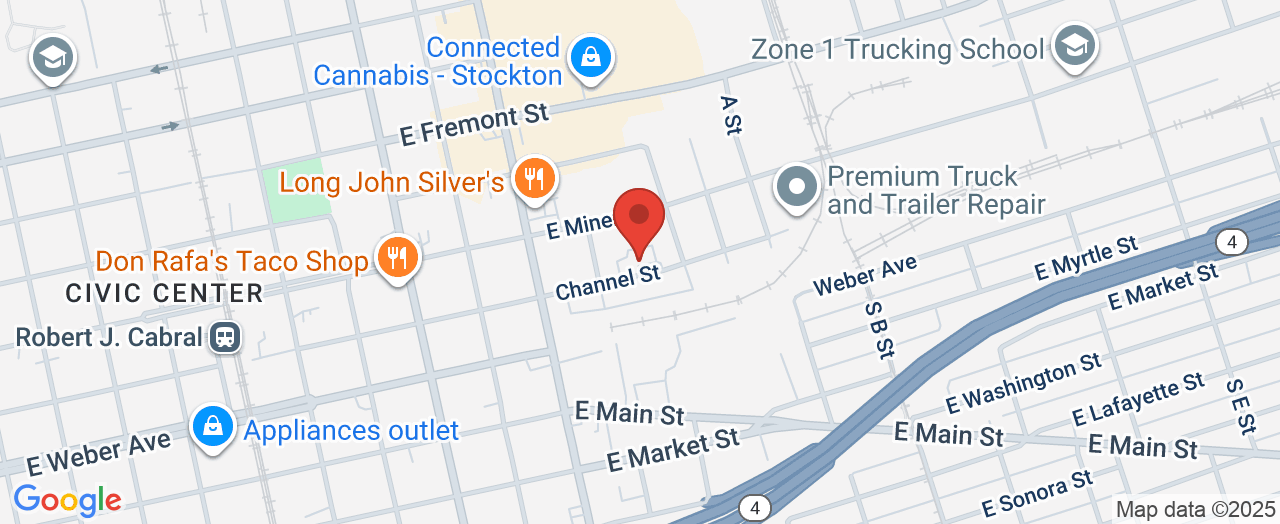

Contact the Experts at Cummins

If you’d like to learn more about how fuel system services could benefit your engine and equipment reliability, contact the team at Cummins.

📍 Address: 1633 Channel St, Stockton, CA 95205, USA

📞 Phone: +1 209-464-8306

🌐 Website: https://righettienterprises.net/

Location and Hours for Cummins

🕒 Hours of Operation:

📅 Monday: 7:00 AM – 5:00 PM

📅 Tuesday: 7:00 AM – 5:00 PM

📅 Wednesday: 7:00 AM – 5:00 PM

📅 Thursday: 7:00 AM – 5:00 PM

📅 Friday: 7:00 AM – 5:00 PM

📅 Saturday: 8:00 AM – 12:00 PM

📅 Sunday: ❌ Closed

Add Row

Add Row  Add

Add

Write A Comment