When Truck Downtime Costs You: Why Engine and Driveline Repair Is Crucial

Every minute a truck sits in the shop instead of rolling down the highway, dollars and time are lost. When engine or driveline problems hit, the stakes rise fast—especially for those who depend on their vehicles for living or managing a fleet. A seemingly minor driveline vibration or engine issue can quickly escalate into a breakdown miles from home, with cargo deadlines and customer trust suddenly on the line. If you’ve ever fretted over that strange thump or warning light, you’re not alone. Engine and driveline repair isn’t just about fixing a part—it’s about keeping life and business moving.

The complexity of modern trucks and trailers means a host of interconnected systems—transmissions, axles, differentials, shafts—that must work in confident harmony. Yet, neglect or piecemeal patching can lead to bigger failures: damaged differentials, loss of power, hazardous handling, or full drivetrain collapse. Understanding what’s under the hood, and under the frame, is essential for anyone responsible for heavy duty vehicles. In a world where logistics depend on uptime, knowing how to identify, address, and prevent these critical issues isn’t just smart—it’s vital to survival in transport or trucking. The value of timely, expert engine and driveline repair can’t be overstated.

Getting to the Heart of the Matter: How Engine and Driveline Repair Keeps You Rolling

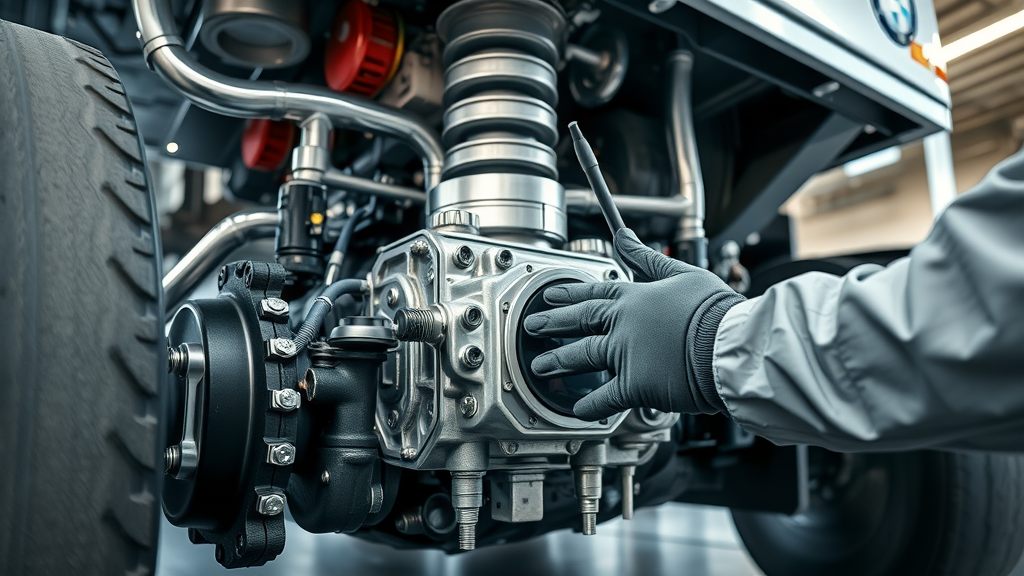

So, what exactly is at stake when we talk about engine and driveline repair? At the core, these are the single most important systems that transfer power from the engine down to the wheels, enabling a vehicle to function at its best. Reliable trucks and trailers rely on an effortless collaboration of components like the transmission, driveshaft, axles, differentials, and more—and even a minor issue with one part can hobble the entire vehicle. When problems emerge—whether it’s a vibrating shaft, loss of torque, or odd gear shifts—the source is seldom isolated: it’s a signal that a deeper inspection and precise repair might be necessary to prevent cascading damage and costly out-of-service time.

This isn’t just theory: failure to recognize the warning signs in your engine or driveline can jeopardize safety, cost thousands in avoidable repairs, and put business operations on pause. In fact, trucks sidelined with powertrain malfunctions or broken drivelines end up costing far more in lost work than the repair bill alone—incurring missed deadlines, damaged reputation, and added stress for operators and fleet managers. For heavy duty vehicles especially, the stakes are high: a breakdown often means more than inconvenience, it can lead to significant logistical snarls or, worse, roadside emergencies. That’s why understanding—and acting on—the need for regular, responsive, and skilled engine and driveline repair is a non-negotiable in transportation today.

Why Comprehensive Engine and Driveline Repair Makes the Difference for Heavy Duty Trucks

As a contributor specializing in truck and trailer service, the approach to engine and driveline repair centers on thorough diagnostics and a breadth of technical capability. From minor shaft adjustments to full transmission rebuilds, the focus is on resolving the issue at its root, not patching symptoms. This kind of comprehensive service recognizes the true value of restoration: not only does it restore the truck to its optimal functional state, but it significantly extends its working lifespan and reliability—all while supporting the vehicle’s daily performance demands.

Properly executed engine and driveline repair means that every component—whether a clutch, axle, or differential—is brought back into precise working order. For truck owners and operators, the result is confidence on every trip, with reduced risk of breakdowns and improved safety. The inclusion of related services such as preventative maintenance, clutch and transmission repair, or full driveline rebuilds ensures that nothing is left to chance. With trucks that are ready to tackle miles instead of sit idle, business continuity is directly protected, demonstrating why robust driveline attention is an investment, not an expense.

From Diagnostics to Rebuilds: What’s Involved in Engine and Driveline Repairs?

It’s easy to underestimate the scope of “engine and driveline repair.” In reality, resolving these issues involves advanced diagnostics, skilled troubleshooting, and hands-on expertise with every layer of a powertrain. Services may include everything from removing and replacing transmissions and differentials, rebuilding drivelines from scratch, resurfacing flywheels for a smoother clutch, or rebuilding hydraulic cylinders for precise control. For heavy vehicles, the repair landscape is broad—think everything from leaks and worn U-joints to catastrophic differential failures or mounting issues.

What sets expert repair apart isn’t just the ability to handle one-off troubles; it’s an approach that considers future reliability, with attention to every connected system: cooling, electrical, suspension, and more. Shop floors dedicated to this kind of work are equipped with specialized tools, up-to-date parts inventory, and service professionals who can rapidly diagnose and execute on a solution. The ultimate value is a repair that lasts—and a return to the road with peace of mind.

Prevention Is Power: The Role of Regular Inspections and Maintenance

Preventive maintenance is the secret ingredient that often separates those fleets that run with minimal disruption from those frequently sidelined. Routine inspections, such as fluid checks, alignment, brake evaluations, and early diagnostics, help pinpoint problems before they spiral into something far costlier. Catching a worn driveshaft component or a leaking seal early, for instance, can save both time and substantial repair costs, especially when vehicles are carrying valuable cargo over long distances.

This process isn’t simply about avoiding issues; it’s about building a culture of reliability and readiness. When a service center prioritizes comprehensive diagnosis—checking not just the obvious, but also potential problem areas—customers get the reassurance that their vehicles will perform under stress. Mandatory DOT inspections, advanced engine diagnostics, and scheduled service intervals all drive home one point: prevention in engine and driveline repair is the most effective kind of problem-solving.

Responding to Emergencies: Roadside and Mobile Engine and Driveline Service

The reality of trucking means problems don’t always arise in the shop or on a schedule. Engine failures, driveline disconnects, or breakdowns on the road can create logistical nightmares—unless there’s a reliable solution at hand. In modern truck service, mobile and roadside repair units have become indispensable. Technicians equipped with diagnostics and repair tools can address issues from transmission to electrical on-site, minimizing downtime and getting vehicles safely to their destination—or back to the shop for deeper fixes.

This form of responsive support is a lifeline for both solo operators and large fleet managers, bridging the gap between problem and solution when every minute counts. From on-the-spot troubleshooting of powertrain issues to emergency hydraulic repairs and driveline rebuilds, real-time service protects drivers, cargo, and company commitments in equal measure. The peace of mind it offers is as real as the practical benefits.

The FleetPride Approach: A Full-Spectrum Philosophy for Engine and Driveline Repair

FleetPride Service Center stands out through a philosophy rooted in capability, reliability, and trust. The mission is straightforward: offer comprehensive solutions to every aspect of heavy duty truck and trailer service, from engine and driveline repair to preventative diagnostics and specialty rebuilds. This approach recognizes the complexity of today’s vehicles—requiring not only expertise in multiple repair types but also a commitment to quality, safety, and long-term vehicle health.

By offering a wide scope of services—think alignments, brake service, A/C, clutch, suspension, and specialty repairs like U-bolt bending or flywheel resurfacing—FleetPride helps keep trucks moving without extended delays or repeated breakdowns. Rooted in a nationwide network, this methodology means not just fixing a single system but integrating repairs with scheduled maintenance, full rebuild capacity, and reliable sourcing of hard-to-find parts. For those depending on their vehicle’s performance every day, this total-care perspective is the foundation of trust.

Stories from the Field: When Engine and Driveline Repair Restores Confidence

Real testimonial stories bring to life the impact that effective engine and driveline repair has on everyday work. For many business owners and operators, the biggest challenge isn’t just mechanical—it’s finding expertise when the issues aren’t straightforward, or the parts aren’t readily available. Here’s how one recent experience stands out:

Had work done on light duty box truck that's hard to find parts for but Tommy and his team were able to fix the suspension and have me back on the road in no time great service and price for quality work!

Stories like these highlight the real outcomes behind every technical fix: a business gets back up and running, confidence is restored, and downtime is kept to a minimum. For anyone considering taking action on engine or driveline issues, the takeaway is clear—the benefits of expert, efficient service are measured in more than just miles; they're felt in everyday peace of mind and long-term reliability. When the stakes are high, having a trusted source for repair can make all the difference for the journey ahead.

Engine and Driveline Repair: The Smart Move for Reliable Trucking

In today’s world of heavy duty transport, engine and driveline repair isn’t optional—it’s a fundamental part of staying competitive and dependable. The challenges are real, but the expertise exists to meet them head-on. FleetPride’s deep commitment to their craft, extensive part sourcing, and diagnostic know-how have positioned them as a reliable authority in truck and trailer care, enabling drivers and businesses to focus on what matters: safe, consistent operation and minimized surprises. When factoring in the cost, time, and peace of mind, engine and driveline repair is not just smart maintenance—it’s essential for a future built on reliability.

Contact the Experts at FleetPride Service Center

If you’d like to learn more about how engine and driveline repair could benefit your vehicle or fleet, contact the team at FleetPride Service Center.

📍 Address: 444 E 100 N, Payson, UT 84651, USA

📞 Phone: +1 801-465-4873

🌐 Website: https://branches.fleetpride.com/ut/payson/truckparts-pyn-sc.html

FleetPride Service Center Location and Availability

🕒 Hours of Operation:

📅 Monday: 7:00 AM – 4:00 PM

📅 Tuesday: 7:00 AM – 4:00 PM

📅 Wednesday: 7:00 AM – 4:00 PM

📅 Thursday: 7:00 AM – 4:00 PM

📅 Friday: 7:00 AM – 4:00 PM

📅 Saturday: ❌ Closed

📅 Sunday: ❌ Closed

Add Row

Add Row  Add

Add

Write A Comment